From initial research to market implementation, our products are differentiated by development using three methodologies:

From initial research and advanced simulations to real-world testing, our solutions undergo rigorous validation processes. Our dedication to continuous development and open innovation allows us to transform ideas into market-ready products based on the technological maturity of our solutions.

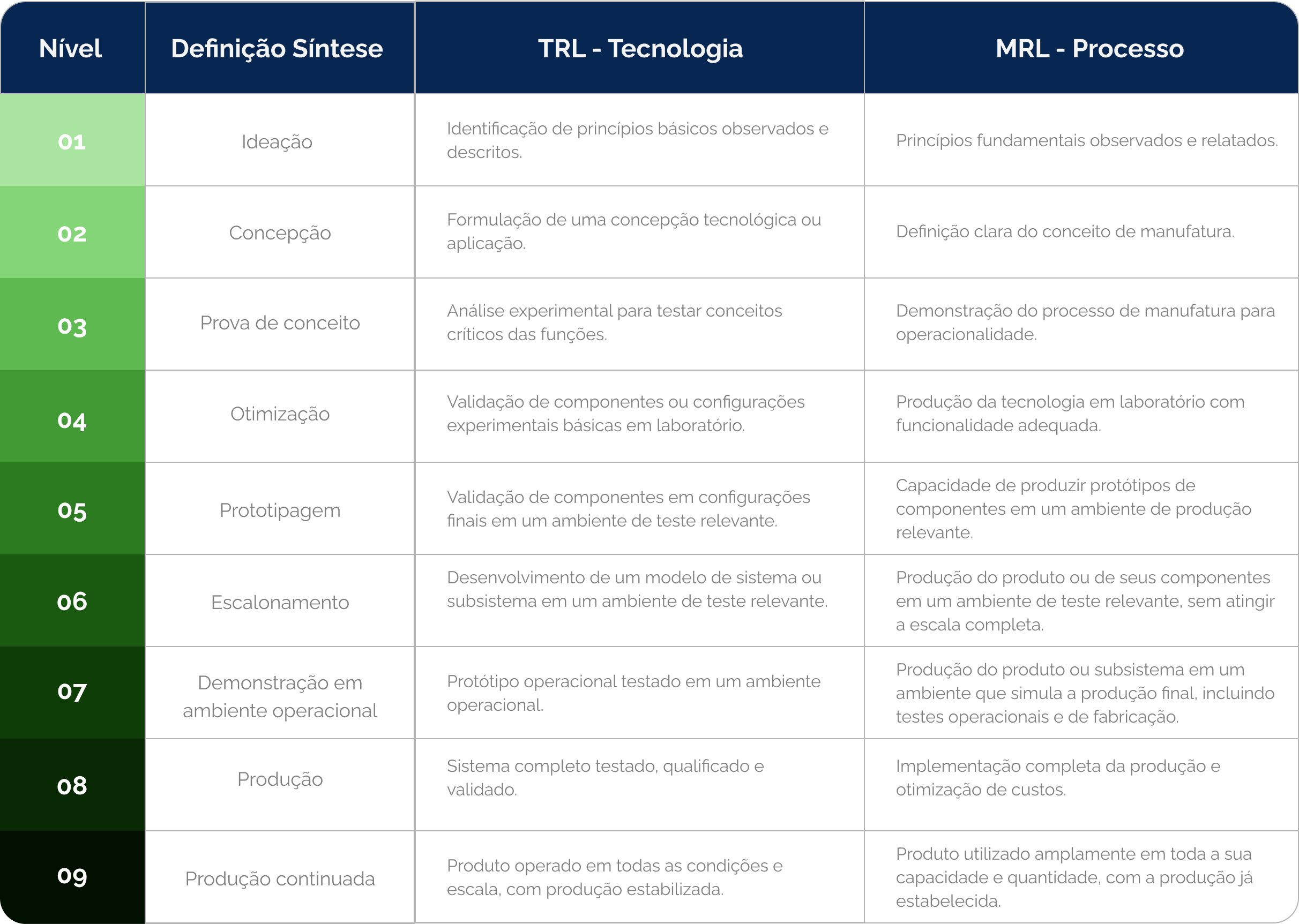

For LLK, the TRL/MRL (Technology Readiness Levels/Manufacturing Readiness Levels) scale is a crucial tool for assessing the technological development of our products and the readiness of production processes. We measure product maturity with the TRL scale and manufacturing process maturity with the MRL scale.

All LLK projects follow the TRL/MRL scale, facilitating clear communication of development stages between managers, teams and partners, guiding the actions required for completion and delivery of solutions. In addition, it helps manage LLK’s innovation portfolio, maximizing business opportunities and technology transfer.

Ideation

Identification of basic principles observed and described.

Fundamental principles observed and reported.

Conception

Formulation of a technological design or application.

Clear definition of the manufacturing concept.

Proof of concept

Experimental analysis to test critical concepts of functions.

Demonstration of the manufacturing process for operability.

Optimization

Validation of components or basic experimental configurations in the laboratory.

Production of technology in the laboratory with adequate functionality.

Prototyping

Validation of components in final configurations in a relevant test environment.

Ability to produce prototype components in a relevant production environment.

Escalation

Development of a system or subsystem model in a relevant test environment.

Production of the product or its components in a relevant test environment, without reaching full scale.

Demonstration in operational environment

Operational prototype tested in an operational environment.

Production of the product or subsystem in an environment that simulates final production, including operational and manufacturing testing.

Production

Complete system tested, qualified and validated.

Complete implementation of production and cost optimization.

Continuous production

Product operated under all conditions and scale, with stabilized production.

Product widely used in all its capacity and quantity, with production already established.

At LLK, we adopt a customer-centric approach that informs all of our operations, from product development to process optimization. This customer focus ensures that each step of development is clear and aligned with customer expectations, facilitating effective communication between managers, teams and partners.

By focusing our activities on customer satisfaction, LLK effectively manages its innovation portfolio, maximizing business opportunities and delivering what truly meets the specific needs of each customer. This principle of CUSTOMER FOCUS not only drives innovation within the company, but also ensures that our solutions are valuable and relevant, strengthening customer relationships and market positioning.

Projects developed to integrate Industry 4.0 technologies, maximizing efficiency and connectivity.

Conditions in conjunction with: (Customer-focused 100% projects) and (Defining the metrics that matter).

Continuous process of improvement in after-sales, remaining by the customer's side with SLA maintenance service contracts.

We actively seek customer feedback, which is essential to guide developments and improvements.

Projects developed to integrate Industry 4.0 technologies, maximizing efficiency and connectivity.

Process of understanding customer needs and expectations to offer robust and effective solutions.

Conditions in conjunction with: (Improving products) and (Defining the metrics that matter).

Projects are developed with total focus on customer needs and satisfaction, from initial demands to after-sales.

Conditions in conjunction with: (Customer-focused 100% projects) and (Defining the metrics that matter).

Continuous process of improvement in after-sales, remaining by the customer's side with SLA maintenance service contracts.

Conditions in conjunction with: (Customer-focused 100% projects) and (Product improvement).

Selection and use of specific metrics (KPIs) to measure the success and impact of projects on customer satisfaction.

We actively seek customer feedback, which is essential to guide developments and improvements.

Process of understanding customer needs and expectations to offer robust and effective solutions.

Projects developed to integrate Industry 4.0 technologies, maximizing efficiency and connectivity.

Conditions in conjunction with: (Customer-focused 100% projects) and (Defining the metrics that matter).

Continuous process of improvement in after-sales, remaining by the customer's side with SLA maintenance service contracts.

Conditions in conjunction with: (Customer-focused 100% projects) and (Product improvement).

Selection and use of specific metrics (KPIs) to measure the success and impact of projects on customer satisfaction.

Conditions in conjunction with: (Improving products) and (Defining the metrics that matter).

Projects are developed with total focus on customer needs and satisfaction, from initial demands to after-sales.

At LLK, we value collaboration as a fundamental pillar of our success, working with both customers and other suppliers who have knowledge and expertise that complement our capabilities in automation, instrumentation and Industry 4.0. This collaborative approach enables the creation of innovative solutions that benefit all parties involved, strengthening ties and expanding our technical capabilities.

By integrating our expertise with that of strategic partners, LLK not only strengthens its market offering but also creates a more robust and efficient innovation ecosystem. These collaborations not only enhance our products and services, but also ensure that they are highly tailored to market demands and the specific needs of each customer. The focus on strategic collaborations not only drives continuous innovation within the company, but also solidifies our position as a leader in advanced, integrated solutions for Industry 4.0.

Specific studies have been carried out with Vale to measure iron content online directly on conveyor belts, providing important data for reagent control and metallurgical recovery. Vale provides data from its laboratory measurements for the development of this system.

A system for monitoring the flow and level of streams and riverbeds throughout the mine area and beyond was developed in conjunction with Samarco. This system is completely wireless and operates using 100% solar energy.

A retrofit of the automation system was designed together with Mosaic, updating sensors, cables, PLCs and electrical power supply to state-of-the-art instrumentation for industrial mobile equipment in environments with dust and water.

Under development, a previously patented system for online structural analysis of equipment that uses metal structures, based on the idea of online monitoring of aeronautical structures, also for the basic industry (NDA in force).

Under development, a previously patented online instrumentation system for various types of rolling elements in mining equipment. The system differs from other existing systems due to its focus on robustness and data accuracy (NDA in force).