At LLK, we recognize that each industry sector has its own challenges, but innovation is a universal necessity. With our expertise in the Internet of Things (IoT), Big Data, and Artificial Intelligence, we are ready to transform your operation into a true Industry 4.0, precise and robust.

Harness the power of intelligent automation and advanced data analytics to streamline processes, increase operational efficiency, improve workplace safety, and reduce resource expenditures, all while supporting decarbonization.

In mining, IoT implementation involves the use of sensors to monitor equipment condition and environmental conditions in real time (online).

Responses from multiple instruments are provided to industrial computers, optimizing equipment maintenance (Proactive Maintenance 4.0), increasing worker safety and maximizing operational efficiency through accurate tracking of equipment and working conditions.

For example, vibration and temperature sensors in various mine and plant equipment can predict failures, allowing preventive maintenance to be carried out and avoiding unexpected shutdowns.

The collection and analysis of large volumes of operational and geological data are sent to industrial computers and new parameters are calculated in milliseconds.

This analysis helps to identify online the condition, for example, of the content and moisture of tailings, complete conveyor belt situations and provides new data for gains in process efficiency, as well as details of deposits with greater precision, optimizing the extraction and processing processes, improving efficiency and minimizing environmental impacts.

Artificial Intelligence is applied to obtain more intuitive analyses, where a complete analysis of the situation was previously required. It is used in mining to optimize equipment analyses, prevent failures in advance, perform predictive and proactive maintenance (direct action on the equipment) and optimize the use of consumables, such as flotation reagents and fuels for transport routes.

One example of AI use is in the analysis of roller and roller failures, which are common in mining. Online temperature and vibration sensors with AI are able to analyze the collected data to identify patterns that indicate wear or imminent failures.

AI ensures operational continuity, reduces maintenance and plant downtime costs, while keeping workers safe.

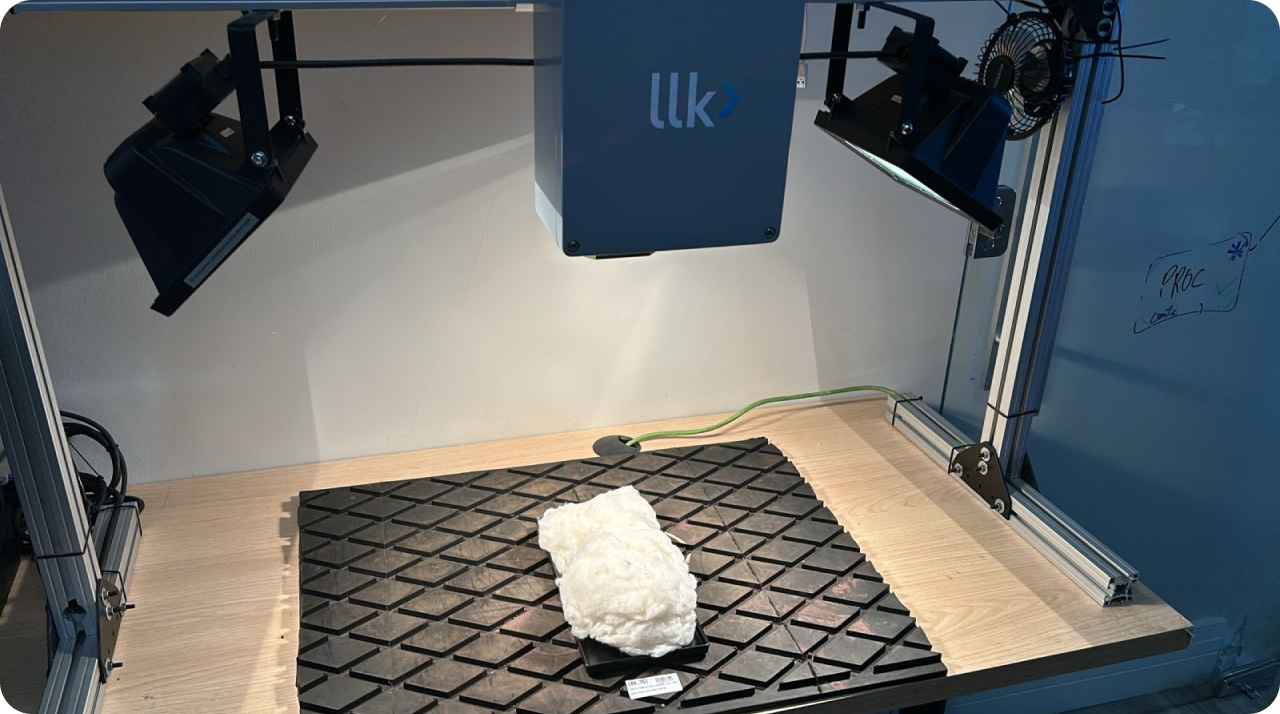

RADEC® Vision

VALE invested in the 3rd generation of RADEC® Vision via Mining Hub starting in 2019 in a Proof of Concept, leading to the product in 2023. During development, tears were detected that achieved payback (return on investment) at the first detection, also adding safety to workers by reducing the need for exposure to risk, as well as contributing to decarbonization by reducing the amount of team and equipment mobilization.

In the steel and metallurgy industry, the implementation of sensors allows real-time (online) monitoring of equipment and process conditions.

For example, sensors installed in blast furnaces can provide data on temperature, pressure and air quality, enabling precise adjustments to optimize production and ensure safety. Temperature measurements and computer vision in hot and cold rolling mills provide insight into production conditions.

Another application is the relationship between slag and pig iron production online, allowing adjustments to improve efficiency and product quality.

Analysis of large volumes of operational data, known as Big Data, is essential to optimize production processes in the steel industry and maintain steel quality.

By collecting and analyzing real-time data from sensors and monitoring systems, steelmakers can gain valuable insights that lead to more efficient and cost-effective production, greater control over manufacturing parameters, reduced material and energy waste, and implementation of effective predictive maintenance to minimize downtime.

Artificial Intelligence plays a crucial role in optimizing production processes and improving automation and operational efficiency.

AI-based systems can predict the need for maintenance of critical equipment, minimizing unexpected downtime and ensuring production continuity.

Furthermore, AI can optimize the mix of raw materials for steelmaking, resulting in more economical production, increasing the competitiveness and sustainability of the steel industry.

RADEC® Vibrational

TERNIUM was the first steel mill in Brazil to invest in high-quality detection of belt tears. When initially selecting its critical belts, it installed RADEC® Vibrational units that, since 2021, have been detecting initial tear situations with high precision, avoiding expenses of tens to hundreds of millions of reais in the complete replacement of its belts. It currently has more than 20 units installed.

In cement manufacturing, IoT uses sensors in equipment such as roller mills and rotary kilns to continuously monitor conditions such as temperature, pressure, and motor speed. These sensors provide real-time data, allowing for immediate adjustments.

For example, vibration sensors in exhaust fans detect imbalances, optimizing production and ensuring safety.

The use of Big Data in the cement industry involves the analysis of large volumes of data generated by chemical composition analyzers and flow meters. This allows for the identification of patterns, monitoring of temperature and chemical composition, and ensuring high product quality.

For example, data from temperature sensors in preheater cyclones helps adjust operations to improve thermal efficiency.

AI automates and optimizes processes in cement manufacturing, controlling rotary kilns and ball mills and predicting maintenance of equipment such as reducers and conveyors. This reduces downtime and maintains cement quality. AI also helps reduce environmental impact, making production more sustainable and efficient.

RADEC® Vision + RADEC® Vibrational Set

CSN Cimentos consulted several companies to fully protect its flying belts. LLK was the only company to offer a complete protection system according to CSN Cimentos' needs. Currently, CSN Cimentos' 7.2 km flying belt, the largest in the world for this category of conveyor, is protected by 100% LLK RADEC® systems.

In the fertilizer, chemical and petrochemical industries, IoT uses sensors in reactors, distillation towers and mixing units to monitor variables such as temperature, pressure and flow in real time.

These sensors allow automatic and immediate adjustments, improving process efficiency and safety.

For example, pressure sensors in pipelines can detect leaks early, preventing accidents and production interruptions.

The use of Big Data in these industries involves analyzing large volumes of data collected from equipment such as chemical reactors and distillation columns. This allows for the identification of patterns, optimization of processes and the assurance of consistent product quality.

For example, analyzing historical data can help adjust operating conditions to maximize the yield of a chemical reaction and reduce operating costs.

AI is applied to optimize and automate processes in the production of fertilizers, chemicals and petrochemicals.

AI systems can predict maintenance for critical equipment such as compressors and pumps, reducing downtime. Additionally, AI helps optimize chemical formulation, improving efficiency and minimizing environmental impact, while ensuring consistent product quality.

Online Colorimeter

Mosaic Fertilizantes requested the development of equipment to quantify, classify and act online on its anti-dusting oil application systems (dust prevention) in its fertilizers. LLK developed an online vision system called Online Colorimeter to accurately measure the amount of oil applied to the fertilizer, classifying it before bagging, ensuring the maximum quality of Mosaic fertilizers.

In the food and beverage industry, IoT uses sensors on production lines, storage tanks, and packaging equipment to monitor variables such as temperature, humidity, and processing speed in real time. These sensors enable automatic adjustments to optimize efficiency and ensure food safety.

For example, temperature sensors in pasteurizers and vibration sensors in centrifuges help ensure that products reach the correct temperature, maintaining quality and safety.

The use of Big Data in the food and beverage industry enables detailed analysis of operational data generated in production and processing lines. This helps to optimize processes, monitor quality and ensure product consistency.

For example, real-time data analysis from multiple quality sensors during production can identify deviations in manufacturing parameters, allowing for immediate adjustments to meet quality and safety standards.

Furthermore, Big Data can be used to adjust cooking and mixing conditions, improving efficiency and reducing waste of raw materials.

AI is used to automate and optimize production processes in the food and beverage industry. AI systems can predict maintenance of equipment such as mixers and packaging machines, reducing downtime.

Additionally, AI can be used to develop new recipes and improve product formulation, ensuring consistent taste and quality while minimizing costs and maximizing operational efficiency.

Volumetric Balance

Mondelez had a specific need to control its bulk food products during conveyor belt transportation. Traditional integrating scales provided incorrect information and were difficult to calibrate, and chocolate production requires precise quantity control. LLK supplied the Volumetric Scale, providing 99.5% precision throughout the process of the volume transported by the conveyor belt, ensuring the quality production of Mondelez products.

In the agricultural industry, IoT uses sensors in agricultural equipment, irrigation systems, and storage facilities to monitor conditions such as soil moisture, ambient temperature, and inventory levels in real time. These sensors enable automatic adjustments, improving the efficiency and productivity of agricultural operations.

For example, moisture sensors in fields can trigger irrigation systems only when necessary, optimizing water use and increasing crop productivity.

The use of Big Data in the agribusiness industry enables the analysis of large volumes of operational data collected from agricultural machinery, soil monitoring systems and climate data. This helps to optimize cultivation processes, improve crop forecasting and ensure product quality.

For example, analyzing historical yield data and soil conditions can help adjust planting and harvesting practices, increasing the efficiency and sustainability of farming operations.

AI in the agribusiness industry is used to optimize cultivation and production processes, such as pest control and fertilizer application. AI systems can predict the need for maintenance of agricultural machinery, reducing downtime.

Additionally, AI helps analyze drone and/or satellite images to identify areas of low productivity and suggest specific interventions, ensuring more efficient and sustainable harvests.

Online Cotton Analysis

LLK was selected by Agrihub (link) to participate in a Proof of Concept program, where LLK was chosen by TMG to verify the possibilities of chemical and physical analysis of cotton online, adding greater speed and precision to the cotton selection and separation process, assisting the samples that were analyzed in the laboratory. Several analyses were performed using hyperspectral cameras with important final conclusive results for TMG.

In the automotive industry, IoT uses sensors on assembly lines, manufacturing robots, and vehicles to monitor conditions such as positioning, parameter analysis, and performance of parts as they are produced, in real time.

Computer vision allows for automatic and immediate verification and adjustments, improving production efficiency and the quality of vehicle parts.

For example, cameras on welding robots can detect positional deviations, ensuring precision and quality in chassis manufacturing.

The use of Big Data in the automotive industry enables the analysis of large volumes of operational data generated by sensors and vehicle test systems. This helps to optimize manufacturing processes and improve quality control.

For example, analyzing engine performance test data can identify patterns that allow fine-tuning of the assembly process, ensuring that each vehicle meets efficiency and safety standards.

AI is used in the automotive industry to optimize and automate production and maintenance processes. AI systems, combined with computer vision, are used to check engine blocks during production.

These systems analyze images of components to detect defects or inconsistencies in real time, ensuring that only high-quality parts advance through the assembly process.

Additionally, AI can predict the need for maintenance of critical equipment on assembly lines, reducing downtime and improving overall production efficiency.

Online 3D scanning of parts

TEKSID has a production line where different parts are positioned manually. Each specific position must receive a part of a certain size. Often, some positions do not receive the parts, or their sizes are changed.

LLK developed an artificial vision system that addressed this problem by identifying the absence of specific parts in positions in different models, as well as classifying them by their diameters and

In the pulp and paper industry, IoT uses sensors in processing equipment and manufacturing machinery to monitor variables such as humidity, temperature, and production speed in real time. These sensors enable automatic adjustments, optimizing efficiency and product quality.

For example, sensors in paper dryers can automatically adjust the temperature to ensure paper moisture is at optimal levels, improving product consistency.

The use of Big Data in the pulp and paper industry involves the analysis of large volumes of data generated by sensors in production machinery, such as digesters and paper machines.

This allows for the optimization of manufacturing processes, such as pulp cooking efficiency and quality control in the formation of paper sheets.

For example, analyzing data from temperature and pressure sensors in digesters can help adjust cooking conditions to maximize pulp yield, reduce energy consumption, and minimize product variability.

AI in the pulp and paper industry is used to optimize production processes and quality control. AI systems, along with computer vision, are applied to inspect paper sheets for defects during manufacturing.

These systems detect irregularities, such as stains or tears, in real time, ensuring that only high-quality products are shipped to the customer.

Additionally, AI can predict the need for maintenance on critical equipment such as presses and refiners, reducing downtime and improving operational efficiency.

Volumetric Balance

Fibria needed to control the amount of material transferred during conveyor belt transportation. Traditional integrating scales did not provide the necessary information and were difficult to calibrate. LLK supplied the Volumetric Scale on several conveyors, providing precise control of each type of material, including chips, sawdust, chopped wood, shavings and others that were transported. The precision on each scale (for each material) was between 97% and 99% of the volume transported by each conveyor belt, ensuring control of the amount of wood on each Fibria conveyor belt.

Sensors are deployed on drilling rigs, refineries and pipelines to collect data on operating conditions such as pressure, temperature and flow.

This information enables remote monitoring, predictive maintenance and process optimization, reducing unexpected downtime and increasing efficiency.

The use of Big Data in the oil and gas industry involves analyzing large volumes of data collected from sensors and equipment in drilling and production operations. This helps to optimize extraction, refining and distribution processes, improve efficiency and reduce costs.

For example, drilling data analysis can identify patterns that help adjust operations to maximize well productivity while minimizing equipment wear and energy consumption.

Another example is the analysis of vibrations and speeds of flexible pipes, essential for production in accordance with international standards of technical associations.

AI in the oil and gas industry is used to optimize extraction, refining, and maintenance operations. AI systems can predict the need for maintenance of critical equipment, such as pumps and compressors, reducing downtime.

Additionally, AI, in combination with computer vision, can be used to analyze images of infrastructure, such as pipelines and platforms, to detect corrosion or structural damage, ensuring the safety and integrity of assets.

Online Pipeline Quality Controller

Technip is one of the world’s leading suppliers of flexible pipes to major oil companies. LLK was selected to develop a complete system for controlling the length and speed of the pipes, as well as recording and analyzing the data for later production analysis. The system was implemented, providing online data crucial to the quality production of Technip’s flexible pipes used in the oil and gas industry.